|

|

Building a Robust Industrial Ethernet Network In Water and Wastewater Treatment Plants

Reliable Benefits & Features for WWTP Management

The control and management of a Water and Wastewater Treatment Plant (WWTP) is a complex task that requires the supervision of human experts. The typical geography of a WWTP covers hundreds of acres. Many older plants and remote stations that previously had no network are now implementing SCADA systems linked with Ethernet.

A reliable Ethernet network within water and wastewater treatment facilities is required in order to:

- Obtain precise data control – any data error may result in the release of pollutants into the environment.

- Acquire flexible connectivity for a typical Supervisory Control and Data Acquisition (SCADA) system linked with a Master Terminal Unit (MTU) and a Remote Terminal Unit (RTU) which will help to perform remote data collection for controlled devices, such as control pumps, gates, aerators, and flow meters/sensors.

- Increase remote monitoring performance with Human Machine Interface (HMI) from remote stations.

Some of the most featured considerations that industrial Ethernet switches would benefit from by using the WWTP management would be the following:

- Redundancy Ethernet network

- Flexible fiber connectivity

- Increase determinism

- Network management

- Advanced event handling

- High reliabilities

- Cost effective

Redundancy Ethernet Network

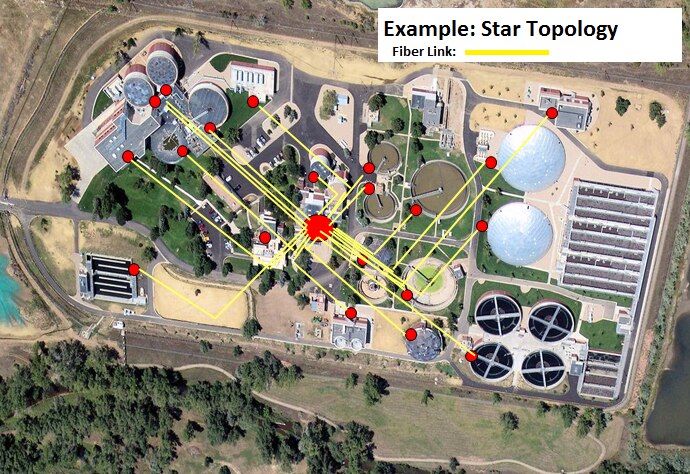

Having a redundant Ethernet network is important to WWTP management, because many WWTPs are still legacy meaning they were either built with a stand-alone station or have a traditional star topology Ethernet network. Valuable data from field devices will be dropped if at any point within a station encounters an accidental cable cut or disconnection.

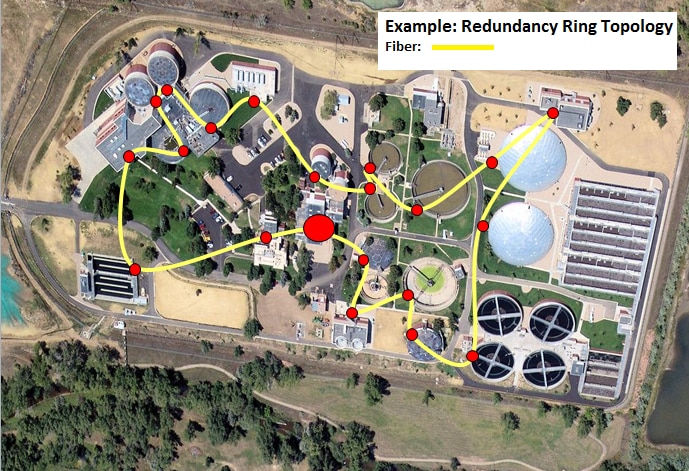

Building a

ring topology redundancy Ethernet network could perform a “Self-Healing” function in order to re-build the network and route data immediately with a backup path. Typically, industrial Ethernet switches have a built-in traditional STP/RSTP network recovery protocol but they still have a limitation for the maximum downtime (2~3 seconds); which means there’s risk about some data being dropped during this period.

For instance, Antaira’s industrial managed Ethernet switches (LNX-802 series) has a specific feature - “Redundant Network”.

The built-in and user-friendly web console allows the user to easily configure the redundant network by just clicking on the drop-down menu and choosing the standard STP/RSTP or Antaira’s ring network recovery protocol setup. The user can assign any uplink ports from switch to switch in order to form a ring topology network.

Benefits: By configuring the redundant network with Antaira’s fast network recovery protocol will allow the WWTP to build a robust network to achieve the self-healing network of less than 20ms (up to 250 switches) to prevent any network downtime or accident shutdown.

Flexible Fiber Connectivity

Wastewater treatment plants networking coverage span for miles upon miles making fiber optic the most beneficial choice when extending the long distance connection from station to station.

The standard Ethernet cable has a limited distance for the cable uplink less than 100M (326ft), but fiber optic cables can have a distance of up to 2Km with a multi-mode fiber, and a distance option from 15Km up to 120Km with a single-mode fiber.

Bandwidth with Fiber Optics

- In the past, the typical wastewater treatment plant network designs for field sites and pump stations was choosing a 100Fx fiber uplink network for low data rate transmission and measurement equipment, such as flow meters, sensors, and valves.

- Today, the consideration of a wider bandwidth network is a trend, due to more field sites and stations devices that require networking. This will help to allow the SCADA system from the administration control center to execute a remote status monitoring and control for devices such as, radio modems, HMIs, PLCs, VoIP, and surveillance cameras.

Benefits with Fiber Optics

- Expanding the distance between the administration center and various stations.

- Preventing electrical noise interference.

- Saving on the fiber cable budget by building a fiber Ethernet ring topology.

Antaira’s industrial managed Ethernet switches provide a wide range of options including 10/100/1000Tx Ethernet in RJ45, and 100Fx or 1000SX/LX fiber connection models with an option of SC, ST, or LC. All models have a rugged design for operating in wide ambient weather and temperature ranges.

- Standard version: 0 to 60˚C

- Extended operating temperature version: - 40 to 75˚C

(Figures below show a network topology with ‘Star’ VS ‘Ring’)

Increase Determinism

To build a reliable Ethernet network within a WWTP, having a redundant network feature is not the only consideration. Having an increase in determinism within the network will help to perform real-time data transmission.

Within the WWTP facilities, measurement devices, control and communication equipment are required to report real-time date to the SCADA system, but other equipment like VoIP or surveillance cameras will not require this.

An industrial managed Ethernet switch with network management software built-in is required in order to increase determinism for all field equipment data transmission.

VLAN 802.1Q

A Virtual LAN (VLAN) is a logical network grouping that limits the broadcast domain, which would allow the user to isolate the network traffic, so only the members of the same VLAN will receive traffic.

Benefits:

Users can segment entire control networks with different substation equipment to transmit data to the same VLAN ID group.

- Effective traffic control

- Enhanced network security

- Simple network management

IGMP Snooping

The Internet Group Management Protocol (IGMP) is an internal protocol of the Internet Protocol (IP) suite. IP manages multicast traffic by using switches, routers, and hosts to support IGMP. Enabling IGMP allows the ports to detect IGMP queries, report packets, and manage IP multicast traffic through the switch.

Benefits:

Users are able to prune multicast traffic equipment data (e.g. PLCs, Video) to travel only to those end destinations that require this kind of traffic.

- Helps to prevent hosts on a local network from receiving traffic for a multicast group they have not explicitly joined.

- Improves the performance and real time response rate.

- Saves network bandwidth.

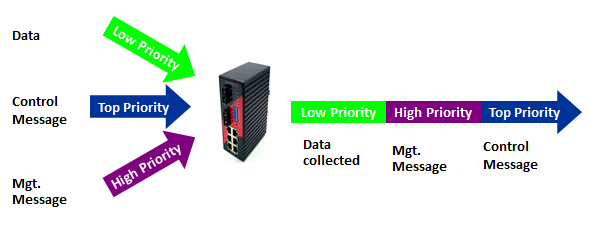

QoS (Quality of Service)

The 8,4,2,1 weight fair queue scheme is used to process the queue with priority from highest to lowest. The system processing is as follows: 1 frame of the lowest queue, 2 frames of the low queue, 4 frames of the middle queue, and 8 frames of the high queue will be processed at the same time in accordance with the 8,4,2,1 policy rule.

Users can prioritize traffic from control devices, such as I/Os, drives or PLCs in high priorities in order to perform real-time control. Devices that are not time-critical such as operator displays, HMIs and supervisory PCs are assigned low priorities. If communication traffic is high, the switch processes the high priority messages before the low priority messages.

Benefits:

- Able to ensure important data is delivered consistently and predictably.

Network Management

This is a web based management console that is user friendly and has a setup and configuration for network online monitoring.

- Allows field engineers to remotely access the switches monitoring the connectivity status.

Advanced Event Handling

System Event Log

Users can set up the mail server IP, mail account, password, and forwarded email account to receive event alerts. In order to receive the alerts, follow the steps below.

- Enable Syslog/SMTP within the switch’s web console, and then the event log will be sent to the system log server/SMTP server.

- For each port log, (link up, link down, and both) events can be sent to the system log server/SMTP server with the respective checkbox ticked.

System Event Type Selection:

- Device cold start

- Device warm start

- Authentication failure

- Network topology change

Port Event Type Selection:

- Link up

- Link down

- Link up and link down

- Power 1 or 2 fail

Benefits:

- Able to allow field engineers to receive event alerts through email at anytime

- Able to remotely login to the switch to check the status

- Able to arrange a schedule for immediate or future maintenance/repair

High Reliabilities

Within WWTP facilities, most of the applications and equipment are in the outdoor environment. The ambient weather will affect the life cycle of equipment in field sites. Although many points will obtain a NEMA enclosure to protect measurement devices and control/communication equipment, a high-grade industrial Ethernet switch with wide temperature operating support is important.

Antaira’s industrial managed Ethernet switches are designed to contain an open IEEE standard, IEC industrial grade test level, a high MTBF, and a wide operating temperature to support a harsh environment ranging from – 40 to 75˚C within any WWTP.

Cost Effective

Antaira’s industrial managed Ethernet switches are designed for industrial outdoor networking purposes that are built with a user-friendly web console design. This design is easy enough for individuals with a limited experience in networking and communications. All of this makes allow for WWTPs to utilize cost effective solutions in everyday applications.

|

|

|

|